| DC Motor and Magnet Control Products |

| OmniPulseTM DDC Digital DC Drive |

Increase your competitive advantage by converting your DC controls to state-of-the-art OmniPulse DDC Digital DC drives.

The leader in crane and hoist motor control, Electromotive Systems, brings you the OmniPulse DDC Digital DC Drive. OmniPulse will improve the

performance and reliability of your DC operated crane or hoist, while minimizing downtime, maintenance expenses and energy costs. OmniPulse DDC

technology may also be applied in other industries. We employ semi-conductor technology, which provides better control of motor speed and torque

than costly, older DCCP control technology. This micro-processor based, solid state, four-quadrant DC-to-DC control is designed for series,

shunt or compound wound motors. More importantly, it will also improve safety in your facility.

Flexible Software

We know production needs change. That's why OmniPulse DDC was designed with universal software that provides superior flexibility during

start-up and allows for quick parameter changes as needed. (Software upgrades or future releases can be flashed from a PC). OmniPulse DDC gives

you optimal performance and speed regulation while adjusting to meet your changing operational requirements - without the need for additional

hardware.

Drop-in Replacement for DCCP

OmniPulse DDC is the perfect drop-in replacement for traditional electromechanical controls, easily interfacing to existing power and control

circuitry using the same connection points in a smaller footprint.

Backed by the Leader - Magnetek

OmniPulse DDC is backed by Magnetek Material Handling's superior application expertise and aftermarket support - available 24/7/365

OmniPulse DDC will help keep your production on track and your costs down. It's the smart choice in crane control that will pay dividends and

provide your facility with a competitive advantage for years to come.

The OmniPulse DDC Advantage

• Improved Motor Speed & Torque Control

• Minimized Downtime & Improved Serviceability

• Reduced Ongoing Maintenance

• Expenses & Energy Costs

• Improved Safety

OmniPulse DDC Digital Crane Controls - Features at a Glance

• Compact, modular design

• Universal software adjustable for various application and production needs

• Built-in diagnostics to troubleshoot crane performance and keep your system up and running

• Standard-closed loop with sensorless feedback - 5% speed regulation

• Optional closed loop with tachometer feedback - 0.1% speed regulation

• May be configured for series, shunt, or compound wound motor applications

• The only DC to DC crane drive available with four-quadrant motor operation

OmniPulse DDC Cost Savings

• Reduction in maintenance costs

- Fewer parts = less maintenance

- Labor savings due to less frequent maintenance required

- Reduced wear on the mechanical drive train

• Improved Reliability/Increased Up-time

- OmniPulse drives use solid-state devices so there are less parts to fail

- Higher reliability in digital technology

- Ease of troubleshooting and diagnostics

- Modular design of the OmniPulse DDC provides easier serviceability

• Inventory Savings

- Reduction in inventory of DCCP component spares

- OmniPulse DDC offers common hardware

- Control & interface board is universal for all sizes

- Two power frame sizes covers entire OmniPulse DDC product offering

• Energy Savings

- Significant energy cost savings can be achieved with the OmniPulse DDC

• Flexibility to Production Requirements

- OmniPulse DDC drives are easily adaptable to changing production requirements

Documentation

• OmniPulse DDC Brochure

• OmniPulse DDC Digital DC Drive Instruction Manual 144-45043

• RPM (Regenerative Power Module) Instruction Manual 144-45117

• OmniPulse DDC Digital DC Drive Application Questionnaire

• Digital DC Drives Diagnostics Tools

• OmniPulse FAQs

|

|

| OmniPulseTM DSD DC Control |

Magnetek's OmniPulse DSD DC Control brings advanced power technology to the operation of DC cranes and hoists.

We've evolved our highly successful DC drive technology, used to power over 25,000 elevator drives worldwide, to bring you a superior DC control

for crane and hoist applications! OmniPulse DSD provides DC shunt wound bridge, trolley, and hoist motors with reliable, energy-efficient

performance, while significantly reducing operating and maintenance costs.

The fully programmable OmniPulse DSD DC drive offers smooth controlled acceleration and deceleration ramps, permitting more efficient load

placement and reduced load swing and mechanical shock. This results in increased production throughput and drive train life.

OmniPulse DSD DC Controls are available in component form, pre-engineered panels, or custom panels designed to your specifications, and include

all standard features plus a wide variety of other control options. DSD also interfaces with IMPULSE Link 4.1 Basic or WDS (wired or wireless),

offering remote parameter operation and diagnostic capabilities.

Safety Advantages

• Motor torque proving at start

• Brake torque proving at start and stop

• Safe Operating Windows reduces the possibility of programming unsafe parameters

• Microprocessor Watchdog Circuit monitors microprocessor operation

• Motor and control protection circuits

• Works with upper limit switches

Maintenance Advantages

• Elimination of contactor problems

• Motor protection circuits

• Elimination of motor in-rush currents reduces demand on collector bars and power centers

• Undervoltage protection

• Saves last 16 faults, automatic reset, or external fault reset

• Reduced mechanical stress

• Elimination of voltage transients caused by magnetic controls

• Microprocessor based built-in diagnostics

• Increased reliability over DC clapper controls and M-G sets

• Built for harsh operating environments

• 2 line x 16 character LCD display in control cabinet as standard

Performance Advantages

• Traverse Motion-programmable, analog or multi-step speed reference

• Hoist Motion-programmable, analog or multi-step speed reference

• Load Float-allows a load to be held aloft at zero speed

• Maximum motor torque from startup to full speed

• Smooth load starting

• Programmable smooth acceleration from minimum to maximum speed

• Programmable smooth deceleration to creep-speed and stop

• MICROSPEED-fine speed control minimizes load swing during operation

• ULTRALIFT-fast no-load hook speeds/easy load spotting

• Built-in Auto Tune-self tunes to motor, faster startup; vital for modernization installation

• Limit switch inputs

• Inching control for exact load placement

• Built-in motor overload protection

Unsurpassed Aftermarket Support

OmniPulse is backed by the industry's best warranty and service, including:

• 24 hour on-call service

• On-site technical support

• Emergency crane control replacement

• One-year warranty

• On-site training programs available

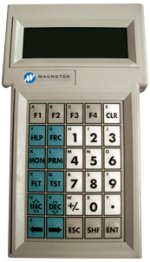

Optional Keypad

• Keypad operator has programmable features and computer diagnostics, allowing the operator to customize

crane and hoist performance

• Display menus provide rapid access to operating status, features, and diagnostics

• Reprogramming parameters is a simple task

• Fault-detection and safety circuits record last 16 faults that may occur and protect motors from dangerous

operating conditions

• Keypad operator displays the control's status, which provides for the fast diagnosis and repair of almost

any problem

• Trouble-shooting is quick and easy with plain language diagnostics

Documentation

• OmniPulse DSD DC Control Brochure

• OmniPulse DSD Instruction Manual 140-10322

• OmniPulse FAQs

|

|

| MagnePulseTM Digital Magnet Control |

Magnetek, the leader in crane and hoist motor control, offers the MagnePulse Digital Magnet Control for the operation of DC industrial

lifting magnets. Built on Magnetek's proven OmniPulse DDC platform, this microprocessor based, solid-state, DC-to-DC control combines

advanced safety and performance features to improve productivity and reliability in your facility.

Advanced Performance

• Digital control of the magnet's demagnetizing current means the magnet cleans the load faster and

more consistently, increasing throughput

• Exclusive OmniBeam feature allows the operator to enable any combination of up to four unique magnets

to precisely match individual load requirements

• Stepped current allows you to program the drive to lift/clean a single slab or a stack of slabs, reducing

cycles and improving throughput

• Power loss ride-through continues to energize the magnet to keep the control running and current flowing

through the magnet when main power is lost

Improved Safety and Protection

• MagnePulse DMC automatically removes magnet power during a fault event, preventing damage to the drive

and magnet

• Open/short circuit detection automatically disables current to the magnet if a cable is cut, avoiding control

and magnet damage while improving plant safety

• Over-temperature protection utilizes the magnet's resistance to determine its temperature, preventing magnet

damage and increasing life expectancy

• Digitally control the rate of current change to prevent voltage spikes or minimize drop time

• Password protection stops unauthorized users from changing the control characteristics

Increased Production and Efficiency

• Reduced lifting current maintains a full load while saving energy, lengthening magnet life, and

increasing average lift capacity

• Efficient use of energy reduces magnet heating up to 50%, reducing or eliminating the need for magnet

change-outs

• Flexible control options include single-input, dual-input, stepped-input, analog or serial current references

as well as a programmable input to maximize magnet and crane performance

• Twenty-five drive, magnet and control status monitors check magnet current, voltage, resistance, temperature,

DC bus voltage, and control variables to simplify process optimization

Enhanced Programmability and Diagnostics

• Comprehensive software provides superior flexibility and allows for quick parameter changes - software

upgrades can be flashed from a PC

• Fully compatible with IMPULSE Link 4.1 Basic and IMPULSE Link 4.1 Wireless Diagnostic System (WDS)

allowing you to upload, download and monitor parameters using a hardwired or wireless link to your PC

Flexible Options

MagnePulse DMC can be easily retrofitted into your current framework, using existing operator controls and connections. Magnetek can also

provide a pre-engineered panel with all the components needed to provide complete magnet control. Panel accessory options include E-stop,

fan kits, and circuit breakers. MagnePulse DMC may also be added to a custom panel, designed and built to your exact specifications.

Documentation

• MagnePulse Digital Magnet Control Brochure

• MagnePulse DMC Industrial Lifting Magnet Control 144-45300

• MagnePulse FAQs

|

|

|

|